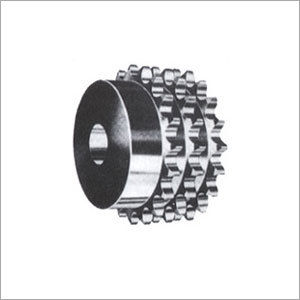

Chain Sprockets

5000.0 INR/Unit

Product Details:

- Bore Size Customized as per requirement

- Usage & Applications Industrial conveyors, Power transmission, Automotive, Machinery

- Product Type Other

- Material Other

- Surface Treatment Polished, Blackodized, Zinc Plated, Hot Dip Galvanized

- Front Gear Available

- Rear Gear Available

- Click to View more

X

Chain Sprockets Price And Quantity

- 1 Unit

- 5000.0 INR/Unit

Chain Sprockets Product Specifications

- Polished, Blackodized, Zinc Plated, Hot Dip Galvanized

- Multiple sizes available as per standard or custom design

- Available

- Industrial conveyors, Power transmission, Automotive, Machinery

- Customized as per requirement

- Available

- Other

- Other

Chain Sprockets Trade Information

- Cash in Advance (CID)

- 100000 Unit Per Month

- 7 Days

- No

- Contact us for information regarding our sample policy

- STANDARD

- All India

- YES

Product Description

Our company brings forth an extensive range of Chain Sprockets, which are manufactured using supreme class raw material To meet the international standards, the raw materials used to manufacture these products are sourced from reliable sources of the industry. These chain sprockets are acknowledged for accurate dimensions, compatibility, perfect finish, high temperature resistance and a longer life and hence the sprockets are highly in demand in the market. Moreover, we offer these sprockets as per the needs of clients at highly competitive prices.

Versatile Material and Surface Treatments

Select from Mild Steel, Carbon Steel, or Stainless Steel sprockets with polished, blackodized, zinc plated, or galvanized finishes. Each material and treatment combination is crafted for optimal strength and resistance to wear and corrosion, ensuring suitability across a wide spectrum of industrial and mechanical applications.

Custom Sizing for Every Application

Our sprockets are available in multiple standard sizes, and we also offer fully custom designs and bore sizes tailored to your specifications. This flexibility ensures seamless integration and functionality across various machinery, conveyors, and power transmission setups.

Trusted Supplier Across Industries

With our reputation as a reliable exporter, manufacturer, and supplier in India, we provide high-quality sprockets nationwide and globally. Our expertise spans numerous sectors, including automotive, industrial automation, and machinery, underscoring our commitment to operational precision and long-term durability.

FAQs of Chain Sprockets:

Q: How do I select the appropriate chain sprocket material for my application?

A: Choosing the right material depends on your operating environment and specific requirements. Mild Steel is cost-effective for general use, Carbon Steel offers enhanced strength, and Stainless Steel is ideal for corrosion-prone or hygienic conditions. Our experts can guide you based on your needs.Q: What surface treatments are available for these sprockets and what are their benefits?

A: We offer polished, blackodized, zinc plated, and hot dip galvanized surface treatments. These finishes provide added protection against rust and wear, improving the sprockets lifespan and reliability under varying industrial conditions.Q: When should I opt for customized bore size or design in sprockets?

A: Customized bore sizes and designs are recommended when standard sprockets do not match your shaft dimensions or require special features for your machinery. Providing accurate measurements ensures a precise fit and optimal performance.Q: Where are your chain sprockets typically used?

A: Our sprockets find applications in industrial conveyors, power transmission assemblies, automotive systems, and a variety of machinery. Their versatility and robust construction make them suitable for any industry requiring reliable chain drive solutions.Q: What is the manufacturing process for your sprockets?

A: We utilize advanced machining and finishing techniques, starting from raw material selection, precision cutting, shaping, and surface treatment. Rigorous quality checks ensure each sprocket meets industrial standards and client specifications.Q: How does using your sprockets benefit industrial or automotive operations?

A: Our sprockets are engineered for durability, high load-bearing capacity, and smooth operation. This translates to reduced downtime, minimal maintenance, and improved efficiency, making them a cost-effective choice for demanding environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS