Half Flexible Gear Couplings

Product Details:

- Thread No internal thread; bolt holes for flange mounting

- Head Code Round

- Connection Coupling with bolts and keys

- Torque Ranges from 200 Nm to 25,000 Nm depending on size

- Sealing No fluid sealing, mechanical tight fit

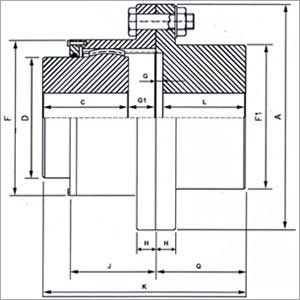

- Bore Customizable as per shaft size, standard range 20mm to 200mm

- Max. Speed Up to 3,500 RPM

- Click to View more

Half Flexible Gear Couplings Price And Quantity

- 1 Unit

Half Flexible Gear Couplings Product Specifications

- Coupling with bolts and keys

- Conforms to AGMA, DIN, or Indian standards

- Machined and Heat Treated

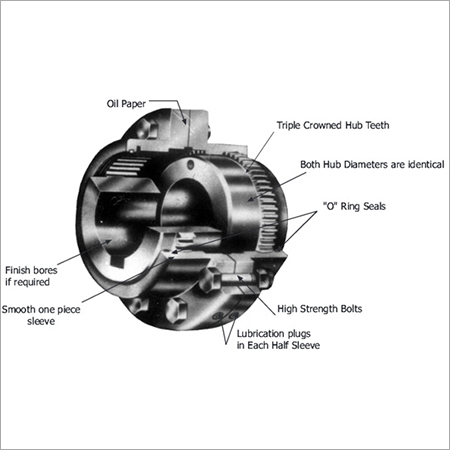

- Half flexible type, gear teeth allow angular misalignment

- Industrial power transmission, mechanical drives, high-torque connections, motors, and pumps

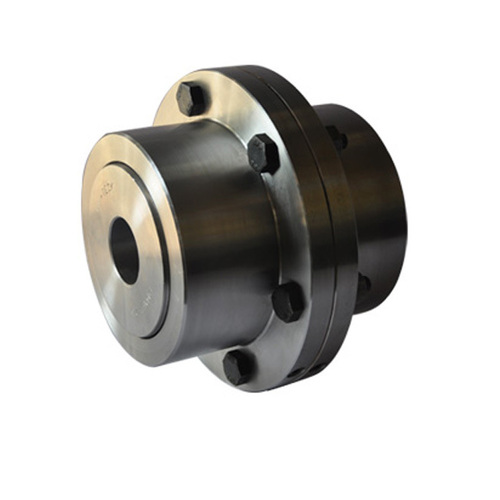

- Cylindrical with gear teeth on one end

- Varies by model, typically 90mm to 320mm

- No internal thread; bolt holes for flange mounting

- Round

- Standard range 20mm to 200mm

- No fluid sealing, mechanical tight fit

- Customizable as per shaft size, standard range 20mm to 200mm

- Up to 3,500 RPM

- Forged alloy steel or carbon steel

- Ranges from 200 Nm to 25,000 Nm depending on size

- Black oxide coated

Half Flexible Gear Couplings Trade Information

- 100000 Unit Per Month

- Days

- All India

Product Description

NU-TECK Couplings Pvt. Ltd is a leading manufacturer and supplier of Half Flexible Gear Couplings which is especially designed for the mechanical power transmission system to transfer the rotational torque in between the driver and the driven element. This mechanical device is machined with latest technologies which offers smoother surface finish and high dimensional accuracy for easy and tight installation. The connection bolts are made up of highly tensile materials which gives higher strength to resist vibrations and forces generated during the rotation.

Specification

Service Factor

Driven Unit (Machinery)

LIGHT :

- Uniform steady load never exceeding horse rating.

- Infrequent starting.

- Agitators, Blowers, Can Filling Machines, Conveyors, Fans, Generators, Pumps, Steering Gears, Stokers.

MODERATE :

- Heavy inertia, moderate shock, frequent starting.

- Peak loads do not exceed 125% average horsepower.

- Uneven load: Ctheadonveyors, Feeders, Welding, Laundry Washers, Mixers, Paper Mills, Printing Presses, Screens, Textile Industry, Car Pullers.

HEAVY :

- Heavy shock conditions or frequent reversing peak loads do not exceed 150% average horsepower.

- Uneven load.

- Cranes & Hoists, Crushers, Dredges, Elevators, Hammer Mills, Lumber Industry,

- Machine Tools, Metal Mills, Oil Industry, Rubber Industry, windlass.

|

Primer Mover |

||

|

Electric Motoror Steam Turbine |

Gasoline or Diesel Engine 4 or mor cyl. |

Gasolineor Diesel Engine more then 6 cyl. |

|

1.0 |

1.5 |

2.0 |

|

1.5 |

2.0 |

2.5 |

|

2.0 |

2.5 |

3.0 |

Engineered for Misalignment and Performance

Half Flexible Gear Couplings allow for angular (up to 1.5) and parallel (up to 0.3mm) misalignments, making them ideal for industrial machinery where shaft alignment can fluctuate. Precision machining ensures a tight, vibration-minimizing fit, while their robust construction withstands challenging environments.

Easy Maintenance and Installation

Designed with user convenience in mind, these couplings are simple to dismantle and reassemble, streamlining routine inspection and lubrication. A grease nipple is provided for ongoing maintenance, significantly extending service life and maintaining peak efficiency in operational settings.

Customizable Solutions for Heavy-Duty Power Transmission

Available with customizable bores (20mm to 200mm) and supporting torque up to 25,000 Nm, these couplings suit a broad range of applications, including mechanical drives, motors, and pumps. Their cylindrical structure, heat treatment, and alloy steel composition guarantee high strength and longevity.

FAQs of Half Flexible Gear Couplings:

Q: How do Half Flexible Gear Couplings manage shaft misalignment in industrial setups?

A: These couplings are engineered with gear teeth and a half flexible design that permits up to 1.5 of angular and 0.3mm of parallel misalignment, effectively accommodating installation inaccuracies and operational shifts.Q: What is the recommended lubrication process for these gear couplings?

A: Routine lubrication is essential; each coupling is fitted with a grease nipple for this purpose. Its advisable to check and replenish the grease during regular maintenance cycles to ensure efficient torque transmission and enhanced durability.Q: When should maintenance or inspection be performed on these couplings?

A: Maintenance should be carried out during scheduled plant downtime or as outlined in the equipments maintenance protocols. Their modular design enables quick dismantling and reassembly, facilitating regular inspection and servicing.Q: Where are Half Flexible Gear Couplings typically used?

A: These couplings are utilized in heavy-duty industrial settings such as power transmission setups, mechanical drives, high-torque motor connections, and pump systems where both reliability and shock-load absorption are critical.Q: What are the key benefits of using these couplings in high-torque applications?

A: Key benefits include superior misalignment tolerance, long service life due to robust heat-treated materials, easy maintenance access, and a precision-machined fit that minimizes vibration and ensures consistent power delivery.Q: How does the black oxide surface treatment benefit the couplings performance?

A: The black oxide coating provides corrosion resistance, enhancing durability in harsh industrial environments and helping maintain the couplings precision fit over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS