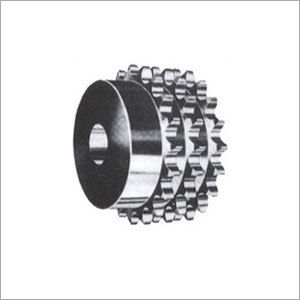

Special Sprockets

10000.0 INR/Unit

Product Details:

- Bore Size Precision machined as per requirement

- Usage & Applications Conveyors, Industrial Machinery, Power Transmission Systems

- Product Type Other

- Material Other

- Surface Treatment Zinc Plated / Blackodised

- Teeth Number Customizable (per requirement)

- Size Customized as per drawing/specification

- Click to View more

X

Special Sprockets Price And Quantity

- 10000.0 INR/Unit

- 1 Unit

Special Sprockets Product Specifications

- Other

- Zinc Plated / Blackodised

- Customized as per drawing/specification

- Conveyors, Industrial Machinery, Power Transmission Systems

- Other

- Customizable (per requirement)

- Precision machined as per requirement

Special Sprockets Trade Information

- 100000 Unit Per Month

- 7 Days

- Asia, Eastern Europe, Western Europe, Middle East

- All India

Product Description

By keeping in track with the market developments, we are offer an extensive range of Special Sprockets. These special sprockets are manufactured utilizing latest tools and technology as per the industry norms. To ensure high quality and durability, these products are subject to stringent quality tests. This range is recognized for its compact design, high dimensional accuracy, corrosion resistance, perfect finish and a long functional life. We offer these sprockets in various specifications to meet the varied needs of clients.

Customized Engineering for Your Needs

Every sprocket is individually crafted to customer-specified sizes, tooth counts, and bore dimensions, guaranteeing a bespoke fit for your equipment. Our expertise ensures the product aligns seamlessly with unique operational requirements, maximizing system efficiency and longevity.

Superior Material and Finishing

We utilize hardened steel for exceptional strength, and offer surface treatment options such as zinc plating and blackodisation for enhanced wear and corrosion resistance. This focus on quality materials and coatings ensures each sprocket performs reliably even in harsh industrial environments.

Versatile Applications Across Industries

Our special sprockets are widely used in conveyors, power transmission assemblies, and industrial machinery. From heavy-duty factories to precision-driven automation settings, these sprockets facilitate smooth motion and dependable performance in various application domains.

FAQs of Special Sprockets:

Q: How are the number of teeth and size of the special sprockets determined?

A: The teeth number and overall size are fully customizable and are manufactured according to your provided drawings or technical specifications. This ensures the sprocket matches your machinerys exact requirements and delivers optimal performance.Q: What materials and surface treatments are available for these sprockets?

A: Special sprockets are made from high-quality hardened steel, providing excellent strength and durability. Surface treatment options include zinc plating for corrosion resistance and blackodisation for enhanced wear protection.Q: Where can these customized sprockets be used?

A: They are suitable for a range of applications, including conveyor systems, industrial machinery, and power transmission mechanisms. Their versatility makes them ideal for any setup requiring durable and precise sprocket solutions.Q: What is the manufacturing process for these custom sprockets?

A: Each sprocket is produced based on your detailed specifications. The process includes precision machining of bore sizes, customization of tooth count, rigorous hardening treatment, followed by the selected surface finishing for maximum service life.Q: When should I consider choosing zinc plated or blackodised treatments?

A: Zinc plating is recommended when additional corrosion resistance is needed, especially in moist or outdoor environments. Blackodised finishes are ideal for enhanced surface protection against wear and abrasion.Q: What are the key benefits of using your special sprockets?

A: Our sprockets offer a tailored fit, robust construction, and long-lasting performance. Their customizable nature, coupled with superior materials and surface treatments, ensure reliability, reduced maintenance, and extended service life in demanding applications.Q: How can I place an order for customized special sprockets?

A: You can contact us with your technical requirements or drawings. As an exporter, manufacturer, and supplier based in India, we cater to clients worldwide with prompt communication and efficient order processing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS