Continuous Sleeve Couplings

Product Details:

- Max. Speed 4000 RPM

- Bore Customized

- Torque Up to 15000 Nm

- Head Code Round

- Sealing Metallic Fit

- Material Carbon Steel / Cast Iron / Alloy Steel / Stainless Steel

- Structure Continuous Sleeve

- Click to View more

Continuous Sleeve Couplings Price And Quantity

- 1 Unit

- 1-100000 INR/Unit

Continuous Sleeve Couplings Product Specifications

- Up to 15000 Nm

- Continuous Sleeve

- Industrial Power Transmission

- Cylindrical Sleeve

- 40mm to 300mm

- Black Oxide

- Customized

- Metallic Fit

- 4000 RPM

- IS 2694:1997 / AGMA / DIN Coupling Standards

- Carbon Steel / Cast Iron / Alloy Steel / Stainless Steel

- Round

- 20mm to 200mm

- Machined

Continuous Sleeve Couplings Trade Information

- 100000 Unit Per Month

- 1 Days

- Maharashtra

Product Description

Backed by the rich industry experience and knowledge, we provide an excellent range of Continuous Sleeve Couplings. These couplings are manufactured at our state-of-the-art manufacturing unit using high grade raw materials. Further, the raw materials we use to manufacture these couplings are procured from reliable sources of the industry. This range of continuous sleeve couplings is respected for its accurate dimensions, compatibility, corrosion resistance, high durability and easy installation.

Specification

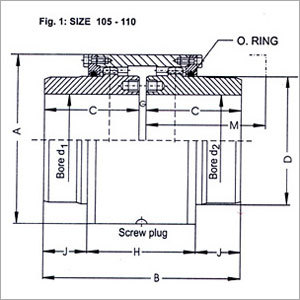

| Common for both Couplings | ||||||||||||

| NU-TECK | H.P. | Max. | Bore | Bore | A | B | C | D | G | H | J | M |

| CSGC-100 | 7 | 8000 | 10 | 32 | 80 | 93 | 45 | 50 | 3 | 57 | 18 | 75 |

| CSGC-101 | 14 | 6300 | 20 | 45 | 110 | 115 | 55 | 65 | 5 | 70 | 22.5 | 90 |

| CSGC-102 | 35 | 5000 | 30 | 60 | 125 | 145 | 70 | 85 | 5 | 76 | 34.5 | 100 |

| CSGC-103 | 63 | 4000 | 40 | 75 | 160 | 175 | 85 | 105 | 5 | 100 | 37.5 | 130 |

| CSGC-104 | 119 | 3350 | 50 | 90 | 185 | 215 | 105 | 130 | 5 | 110 | 52.5 | 150 |

| CSGC-105 | 182 | 2800 | 60 | 110 | 210 | 230 | 110 | 155 | 10 | 122 | 54 | 160 |

| CSGC-106 | 280 | 2500 | 75 | 125 | 240 | 260 | 125 | 175 | 10 | 142 | 59 | 190 |

| CSGC-107 | 490 | 2100 | 90 | 140 | 270 | 290 | 140 | 205 | 10 | 166 | 62 | 220 |

| CSGC-108 | 630 | 1900 | 105 | 160 | 300 | 320 | 155 | 230 | 10 | 176 | 72 | 240 |

| CSGC-109 | 780 | 1700 | 125 | 180 | 340 | 340 | 165 | 250 | 10 | 180 | 80 | 240 |

| CSGC-110 | 1150 | 1400 | 140 | 220 | 400 | 370 | 180 | 310 | 10 | 200 | 85 | 270 |

Precision Engineering for Heavy-Duty Applications

Continuous Sleeve Couplings are expertly machined to offer seamless alignment and high power transmission capabilities. Their robust structure and metallic fit sealing make them ideal for demanding industrial environments where reliability and precision are essential.

Comprehensive Material and Size Customization

These couplings are available in a broad range of materials, including carbon steel, cast iron, alloy steel, and stainless steel, ensuring compatibility with diverse operational requirements. Customizable inner and outer diameters allow for perfect shaft integration and optimum load distribution.

International Standards Compliance

Manufactured to meet IS 2694:1997, AGMA, and DIN coupling standards, these couplings guarantee consistent performance and interchangeability. The strict adherence to international standards ensures quality, safety, and reliability across all supplied units.

FAQs of Continuous Sleeve Couplings:

Q: How are continuous sleeve couplings used in industrial power transmission systems?

A: Continuous sleeve couplings connect two shafts to transmit power seamlessly between rotating equipment, ensuring reliability in heavy-duty applications such as pumps, compressors, and conveyors.Q: What benefits does the black oxide surface treatment provide for these couplings?

A: The black oxide finish enhances the couplings resistance to corrosion and wear, extending the service life and maintaining optimal performance in harsh industrial environments.Q: When should you choose a customized bore for your coupling application?

A: Customizing the bore diameter is recommended when your shaft sizes vary from standard measurements, ensuring a precise fit and optimal torque transmission for your specific setup.Q: Where can these continuous sleeve couplings be installed?

A: They are suitable for installation in a variety of industrial settings, including manufacturing plants, refineries, and power stations where robust and reliable shaft connections are essential.Q: What is the process for manufacturing these couplings?

A: Each coupling is carefully machined from high-quality carbon steel, cast iron, alloy steel, or stainless steel, then treated with black oxide and manufactured to comply with international standards.Q: What are the advantages of the continuous sleeve structure in these couplings?

A: The continuous sleeve design offers smooth torque transmission, minimized backlash, improved shaft alignment, and higher strength, leading to enhanced reliability and longer service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS