Nuflex Flexible Brake Drum Gear Coupling

Product Details:

- Head Code Round

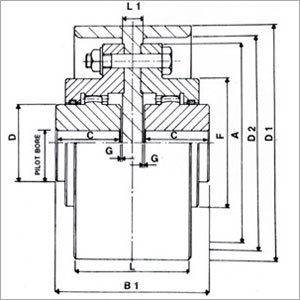

- Max. Speed Up to 4000 RPM depending on size

- Connection Flanged

- Torque Up to 90000 Nm (varies by model/coupling number)

- Bore Customized to requirement or standard sizes

- Material Forged steel/EN9/En24/Alloy steel

- Structure Gear coupling with integrated brake drum

- Click to View more

X

Nuflex Flexible Brake Drum Gear Coupling Price And Quantity

- 1 Unit

Nuflex Flexible Brake Drum Gear Coupling Product Specifications

- Round

- Up to 4000 RPM depending on size

- Gear coupling with integrated brake drum

- Flanged

- Round

- Forged steel/EN9/En24/Alloy steel

- As per brake drum size (e.g., 160 mm to 500 mm)

- Flexible mechanical power transmission, especially for brake drum and gear coupling integration

- Up to 90000 Nm (varies by model/coupling number)

- IS 513 or as per application

- As per coupling size (e.g., 40 mm to 160 mm)

- Customized to requirement or standard sizes

- Machined & Hardened

Nuflex Flexible Brake Drum Gear Coupling Trade Information

- Cash on Delivery (COD), Cash in Advance (CID), Cheque

- 100000 Unit Per Month

- Days

- All India

Product Description

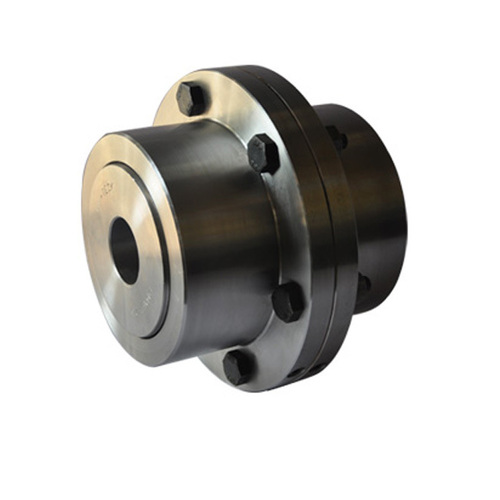

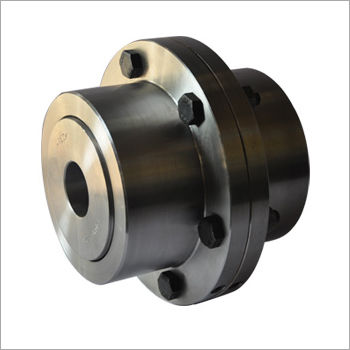

Our customers can avail from us best quality Nuflex Flexible Brake Drum Gear Coupling. It is manufactured from high grade raw material procured reliable sources of the industry as per the defined guidelines of global market. This flexible brake drum gear coupling is appreciated for better durability, compatibility, high tensile strength and accurate dimensions. The entire range is available in various specifications to meet the varied needs of the clients at highly competitive prices.

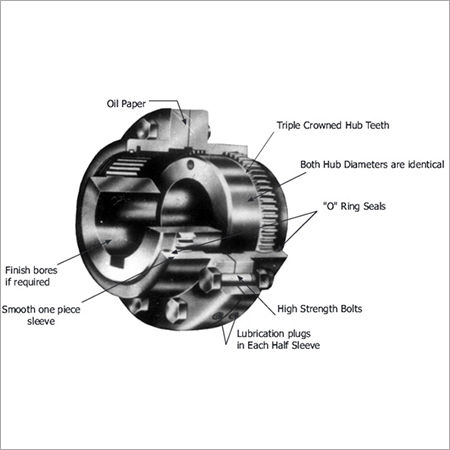

Integrated Design for High Performance

Nuflex Flexible Brake Drum Gear Coupling combines the flexibility of a gear coupling with the functionality of a brake drum, optimizing space and simplifying mechanical layouts in power transmission setups. Its integrated design reduces alignment issues, provides efficient torque transmission, and streamlines system maintenance. The coupling meets rigorous industrial standards ensuring reliability in demanding applications.

Customizable for Varied Industrial Needs

With options for customized bores and diameters, Nuflex couplings can be precisely matched to project specifications. Manufactured using quality-forged steels like EN9 and EN24, these couplings can be machined and hardened as needed, catering to specialized requirements. This adaptability allows deployment across multiple sectors that need robust, high-torque, and high-speed gear coupling solutions.

FAQs of Nuflex Flexible Brake Drum Gear Coupling:

Q: How do Nuflex Flexible Brake Drum Gear Couplings function in mechanical systems?

A: Nuflex Flexible Brake Drum Gear Couplings provide flexible mechanical power transmission by accommodating slight misalignments between connected shafts while simultaneously acting as an integral brake drum. This dual functionality facilitates efficient torque transfer and enables braking within compact spaces.Q: What are the primary benefits of integrating a brake drum with a gear coupling?

A: Integrating a brake drum with a gear coupling streamlines the assembly, reduces installation space, and minimizes potential misalignment. It also simplifies maintenance and boosts system reliability by consolidating key functions into one robust unit.Q: When should I choose a customized bore or diameter for this coupling?

A: Customized bores or diameters are recommended when standard sizes do not match your specific shaft or brake drum dimensions. Opting for a tailored configuration ensures optimal fit and performance for unique machinery layouts and load requirements.Q: Where are these couplings typically used?

A: Nuflex Flexible Brake Drum Gear Couplings are widely utilized in industries such as steel plants, material handling, cranes, conveyors, and other heavy-duty equipment requiring secure, flexible power transmission and integral braking capability.Q: What is the manufacturing process for these couplings?

A: These couplings are precision machined and hardened from forged steel, EN9, EN24, or alloy steel according to IS 513 or application-specific requirements. The process includes careful fabrication of the gear teeth and brake drum to ensure durability and precise operation.Q: How should these couplings be maintained during operation?

A: Regular inspection for wear, proper lubrication of gear teeth, and monitoring of brake drum condition are recommended. Periodic maintenance, as per manufacturer guidelines, ensures long-lasting, trouble-free performance.Q: What are the usage limitations regarding speed and torque for this coupling?

A: Depending on the size and model, the couplings support speeds up to 4000 RPM and torque ratings as high as 90000 Nm. Choose the appropriate model using your systems speed and torque requirements to guarantee safe and efficient operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS