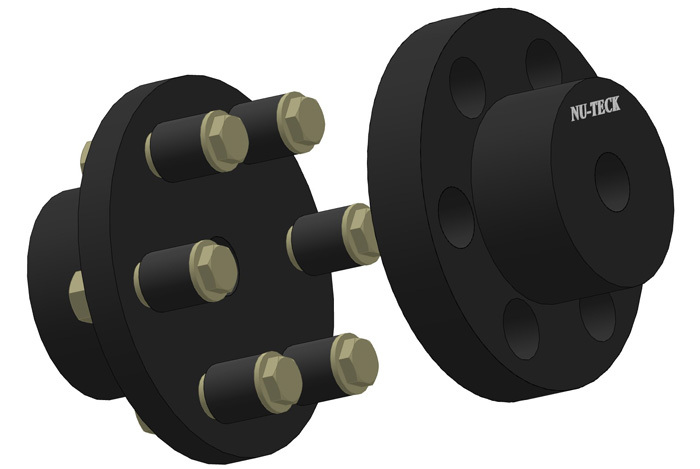

Roller Chain Sprocket

15000.0 INR/Unit

Product Details:

- Usage Industrial

- Material Steel

- Size Standard Sizes

- Product Type Roller Chain Sprocket

- Color Silver

- Surface Treatment Painted

- Click to View more

X

Roller Chain Sprocket Price And Quantity

- 1 Unit

- 15000.0 INR/Unit

Roller Chain Sprocket Product Specifications

- Roller Chain Sprocket

- Silver

- Standard Sizes

- Industrial

- Painted

- Steel

Roller Chain Sprocket Trade Information

- Cash in Advance (CID), Cheque, Delivery Point (DP), Cash on Delivery (COD)

- 100000 Unit Per Month

- 7 Days

- No

- Contact us for information regarding our sample policy

- STANDARD

- All India

- YES

Product Description

Leveraging on our vast industry experience, we provide Roller Chain Sprocket that is widely used in various industries including textile, paper and others. Our roller chain sprocket is designed by our skilled professionals in conformity with the international standards using world class raw material. We offer this chain sprocket in various specifications as per the needs of clients. Known for its optimum performance, longer service, low maintenance, corrosion resistance, dimensional accuracy and easy installation, this is widely in demand in the market.

Precision Engineering & Versatile Options

This sprocket is designed with meticulous attention to detail to ensure seamless integration into various systems. Both front and rear gears are available, providing flexibility in application across a broad spectrum of industrial machinery. Customization options for size and bore guarantee a precise fit for your needs.

Enhanced Surface Finish for Longevity

A polished surface treatment not only elevates the visual appeal but also safeguards against premature wear and corrosion. The quality of the finish enhances performance and extends the operational life of the sprocket, ensuring consistent and reliable use in even demanding environments.

FAQs of Roller Chain Sprocket:

Q: How is the roller chain sprocket with 15 teeth used in industrial applications?

A: This 15-teeth roller chain sprocket is commonly fitted onto machinery in industrial environments to transmit mechanical power, synchronize motion, and transfer torque efficiently, especially in material handling systems.Q: What are the advantages of choosing a mild steel sprocket with a polished finish?

A: Mild steel ensures optimal strength and durability, while the polished surface offers added resistance to corrosion and reduces friction, extending both the sprockets lifespan and operational reliability.Q: When should I select the front gear or rear gear option for the sprocket?

A: The choice between front and rear gear configurations depends on your systems design and mechanical requirements. Selecting the correct configuration aligns with your drive arrangement and optimizes power transmission.Q: Where is this sprocket manufactured and supplied from?

A: This product is manufactured, exported, and supplied from India, catering to both domestic and international industrial markets.Q: What is the process for ordering a custom-size sprocket?

A: To order a custom-size sprocket, provide your specific requirements, including tooth count, bore size, and any special dimensions, to the manufacturer. They will then engineer the sprocket to meet your custom specifications.Q: What are the primary benefits of using this sprocket in material handling systems?

A: Employing this sprocket enhances efficiency and precision in power transmission within material handling systems, leading to reduced downtime and improved overall system performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS