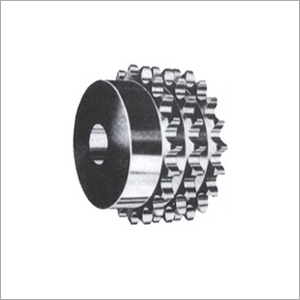

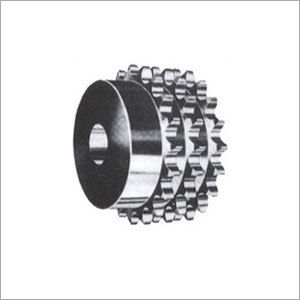

Standard Sprockets

10000.0 INR/Unit

Product Details:

- Usage & Applications Industrial

- Product Type Standard Sprockets

- Warranty 1 Year

- Size Standard

- Click to View more

X

Standard Sprockets Price And Quantity

- 10000.0 INR/Unit

- 1 Unit

Standard Sprockets Product Specifications

- Standard

- 1 Year

- Standard Sprockets

- Industrial

Standard Sprockets Trade Information

- 100000 Unit Per Month

- Days

- All India

Product Description

Our company offers Standard Sprockets which is designed and developed with high precision and accuracy for the efficient transfer of the rotational power in between two shafts. Premium quality carbon steel is used for the fabrication of this drive element which ensures a longer run without any damages. It is widely used in chain transmission system to transfer the power when the driving and driven element are located at a distance from each other due to the machine orientation.

Comprehensive Sprocket Solutions

Our sprockets are designed for high performance in industrial environments, suitable for both dry and mildly corrosive conditions. With a smooth or rough finish as desired and hardness up to 60 HRC, they ensure robust operation and longevity. The range encompasses single- and multi-row structures, with compatibility for plain, taper, or finished bores, as well as keyway or clamp connections.

Custom-Built for Your Application

We offer full customization on sprocket dimensions, groove types, and surface treatments such as phosphating, zinc plating, blackodizing, anodizing, and paint coating. Send us your application details or engineering drawings, and we will deliver sprockets precisely tailored to your needs, ensuring optimal fit, performance, and longevity in your systems.

Global Quality with Reliable Delivery

As manufacturers, exporters, and suppliers based in India, we adhere to stringent industrial standards (ANSI, DIN, BS) and quality processes. Sprockets are securely packaged in your preferred methodcarton, wooden box, or customizedto ensure damage-free worldwide shipping. Experienced in serving multiple industries, we provide ongoing technical support and seamless reordering.

FAQs of Standard Sprockets:

Q: How can I select the right sprocket type and size for my machinery?

A: To choose the appropriate sprocket, consider your applications tooth count (880), pitch (6.35 mm25.4 mm), required bore size (12 mm125 mm), and whether you need simplex, duplex, or triplex. Also factor in your machinerys maximum speed and torque requirements. Our team can assist by reviewing your specifications or engineering drawings to ensure the perfect fit.Q: What materials and finishes are available for standard sprockets?

A: Sprockets can be manufactured from carbon steel, alloy steel, stainless steel, or cast iron, depending on the applications strength, wear resistance, and environment needs. Available finishes include phosphating, zinc plating, blackodizing, anodizing, and paint coating, offering various levels of corrosion protection and durability based on your working conditions.Q: When should sprockets be customized rather than using standard models?

A: Customization is recommended when your equipment has unique dimensions, special grooving needs, or requires a non-standard surface finish or bore type (such as plain, taper, or finished bore). Custom sprockets ensure compatibility, enhance performance, and minimize maintenance in specialized or demanding environments.Q: Where are these sprockets suitable for use?

A: Our sprockets are engineered for power transmission applications in industrial machinery, conveyors, and automated systems. They perform reliably in dry, lubricated, or mildly corrosive environments, making them versatile for use in factories, processing plants, and material-handling installations.Q: What is the process for ordering customized sprockets?

A: Provide us with your technical requirements or engineering drawing. We will review the details, confirm specifications such as tooth count, pitch, groove type, bore size, and surface treatment, and offer a quotation. Upon approval, manufacturing commences, followed by quality checks and secure packaging for delivery.Q: How do these sprockets benefit my power transmission system?

A: Our sprockets deliver efficient, reliable power transmission, reducing energy loss and ensuring smooth drive operation. Their robust materials, precise machining, and adaptability to various mounting and connection methods contribute to longer service life and reduced downtime in your systems.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS