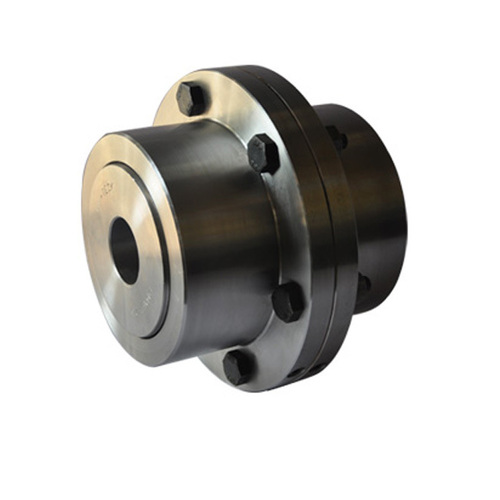

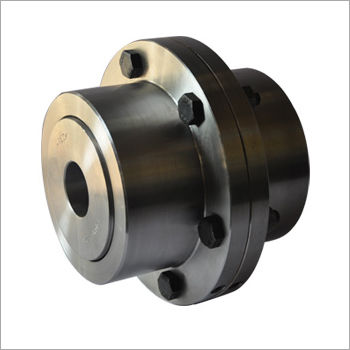

Spacer Type Gear Coupling

25000.0 INR/Unit

Product Details:

- Max. Speed Up to 6000 RPM RPM

- Bore Customized, Range: 10mm to 300mm

- Sealing Optional Grease Seal

- Head Code Round

- Connection Flanged / Splined

- Material Forged Steel / Alloy Steel

- Structure Spacer Type Flexible Gear Coupling

- Click to View more

X

Spacer Type Gear Coupling Price And Quantity

- 25000.0 INR/Unit

- 1 Unit

- Angular up to 1.5, Parallel up to 0.5 mm

- Varies with size, approx. 5 kg to 975 kg

- 100 mm to 1500 mm (as per requirement)

- GCH 102 to GCH 1250 or as specified

- Grease Packed

- -20C to 150C

- Long Designed for continuous operation

- Rust Preventive Coated

- Black / Grey finish

- Pilot Bore / Finished Bore with Keyways / Taper bore

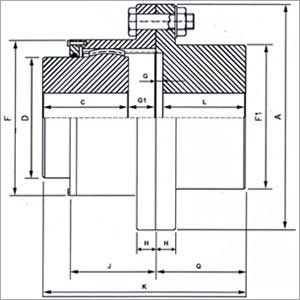

Spacer Type Gear Coupling Product Specifications

- Up to 6000 RPM RPM

- Up to 300 mm Millimeter (mm)

- AGMA / IS / DIN Standards

- Optional Grease Seal

- Customized, Range: 10mm to 300mm

- Round

- Forged and Precision Machined

- Round with Spacer Sleeve

- Other

- Power Transmission, Industrial Machinery, Pumps, Compressors, Conveyors, and Heavy Duty Drives

- Spacer Type Flexible Gear Coupling

- Up to 600 mm Millimeter (mm)

- Forged Steel / Alloy Steel

- Flanged / Splined

- Angular up to 1.5, Parallel up to 0.5 mm

- Varies with size, approx. 5 kg to 975 kg

- 100 mm to 1500 mm (as per requirement)

- GCH 102 to GCH 1250 or as specified

- Grease Packed

- -20C to 150C

- Long Designed for continuous operation

- Rust Preventive Coated

- Black / Grey finish

- Pilot Bore / Finished Bore with Keyways / Taper bore

Spacer Type Gear Coupling Trade Information

- 100000 Unit Per Month

- Days

- All India

- ISO 9001:2015

Product Description

Spacer Type Gear Coupling availed by our company is designed by using heavy engineering materials and advanced machining technologies which makes sturdy, durable and highly dimensionally accurate so that it can be installed very easily with the help of conventional tools. It has a long cylindrical structure which is provided with flanged sleeves to make tight connections for the safe functioning at higher speeds. Buy from us this heavy duty transmission component in large quantities at a reasonable price.

Superior Flexibility and Misalignment Handling

This gear coupling is engineered to accommodate both angular (up to 1.5) and parallel (up to 0.5 mm) misalignment, which protects connected equipment from harmful stress. Its spacer sleeve design allows for easy installation in systems with larger shaft-to-shaft distances, ensuring operational efficiency and minimizing vibration or wear.

Robust Construction and Long Service Life

Manufactured from forged or alloy steel and coated with rust preventive finishes like blackodising, phosphating, or painting, the coupling offers exceptional durability in harsh environments. The grease-packed structure supports continuous operation and reduces the need for frequent maintenance, translating into reduced downtime and operational costs.

Versatile Applications across Industries

Tailored for a variety of industrial sectors, the coupling is widely used in power transmission, heavy-duty machinery, pumps, compressors, and conveyor systems. Its customized bore and connector options, including pilot, finished, or taper bore with keyways, facilitate easy integration into diverse equipment setups.

FAQs of Spacer Type Gear Coupling:

Q: How does the Spacer Type Gear Coupling handle misalignment between connected equipment?

A: The coupling is designed to accommodate angular misalignment up to 1.5 and parallel misalignment up to 0.5 mm, protecting machinery from excessive stress and ensuring smooth power transmission even when perfect alignment is not possible.Q: What is the process for selecting the appropriate spacer length and size for my application?

A: Spacer length (100 mm to 1500 mm) and coupling size (GCH 102 to GCH 1250) are chosen based on the required axial distance between shafts and the systems torque, speed, and bore requirements. Consulting the manufacturer or supplier with your machinery specifications ensures optimal fit and performance.Q: When is it necessary to lubricate or maintain the gear coupling?

A: These gear couplings are grease-packed and designed for long service life with minimal maintenance. It is recommended to inspect and, if necessary, replenish lubrication at routine maintenance intervals based on usage and environmental conditions, optimizing the couplings longevity.Q: Where can this gear coupling be used effectively?

A: The Spacer Type Gear Coupling is ideal for use in industrial applications such as power transmission units, pumps, compressors, conveyors, and heavy-duty drives, particularly where theres a need to bridge large shaft distances or handle misalignment.Q: What are the key benefits of using this spacer type gear coupling in industrial setups?

A: Key benefits include high torque transmission capacity, long operational life, flexibility to accommodate misalignment, reduced vibration and wear, easy installation or removal due to the spacer sleeve, and compatibility with various bore and end connection configurations.Q: What surface treatments and finishes are available for corrosion protection?

A: The coupling is available with several protective finishes, including blackodised, phosphated, painted, and anti-rust coatings, ensuring resistance against corrosion and wear in demanding industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free