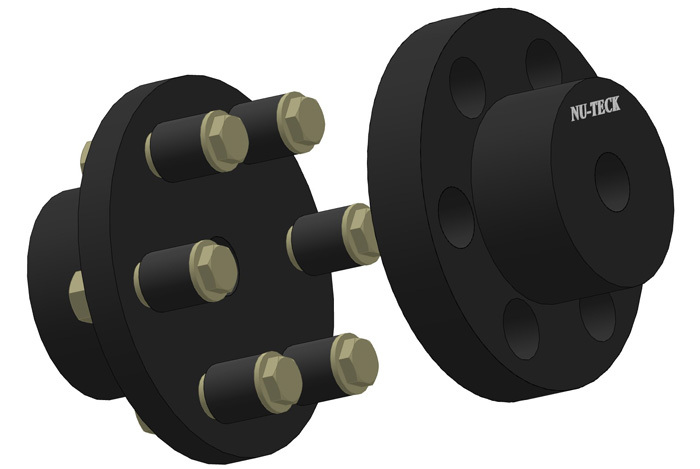

Roller Chain Flexible Coupling

Product Details:

- Head Code Round

- Bore Pilot Bore, Finished Bore

- Max. Speed Up to 3,500 RPM RPM

- Connection Other

- Sealing No Sealing

- Material Other

- Structure Other

- Click to View more

Roller Chain Flexible Coupling Price And Quantity

- 1 Unit

- 15000.0 INR/Unit

Roller Chain Flexible Coupling Product Specifications

- Other

- Round

- Other

- Pilot Bore, Finished Bore

- Other

- Round

- Power Transmission, Machinery Coupling, Conveyors, Industrial Equipment

- As per customer requirement (commonly 19 mm to 55 mm) Millimeter (mm)

- Up to 3,500 RPM RPM

- Other

- As per model selection (commonly 75 mm to 200 mm) Millimeter (mm)

- Other

- IS 2403, ANSI, DIN, ISO

- No Sealing

Roller Chain Flexible Coupling Trade Information

- Cash in Advance (CID)

- 100000 Unit Per Month

- 1 Days

- Eastern Europe, Western Europe, Middle East, Asia

- All India

Product Description

We feel proud to introduce ourselves as the leading manufacturer and exporter of Roller Chain Flexible Coupling. This product is known for its dimensional accuracy, compact design, compatibility, high tensile strength and a longer service life. To manufacture this roller chain flexible coupling, we use world class raw material with the help of cutting edge technology under the guidance of experienced professionals. Moreover, we offer this flexible coupling in different sizes to meet the varied needs of the clients.

Technical Specification

|

Coupling No. |

ASA No. |

A |

B |

Wt. Kg. |

|---|---|---|---|---|

|

NT 6112 |

3812 |

69 |

59 |

0.2 |

|

NT 8312 |

4012 |

75 |

68 |

0.2 |

|

NT 8316 |

4016 |

90 |

70 |

0.4 |

|

NT 1016 |

5016 |

114 |

86 |

0.6 |

|

NT 1018 |

5016 |

123 |

90 |

0.8 |

|

NT 1218 |

6018 |

149 |

93 |

1.2 |

|

NT 1222 |

6022 |

173 |

110 |

1.6 |

|

NT 1618 |

8018 |

195 |

135 |

2.3 |

|

NT 1622 |

8022 |

222 |

134 |

2.4 |

|

NT 2020 |

10020 |

258 |

174 |

3.4 |

|

NT 2418 |

12018 |

292 |

218 |

5.9 |

|

NT 2422 |

12022 |

340 |

212 |

7.3 |

|

NT 3218 |

16018 |

385 |

250 |

14 |

|

Service |

Driven equipment |

Source of power |

|||

|---|---|---|---|---|---|

|

kinds |

characteristics |

Electric motor |

Steam or |

Diesel or Gas |

|

|

A |

Centrifugal fans, blowers of pumps |

Even load - 8 hours/day service, Non-reversing-low |

1 |

1.5 |

2.0 |

|

B |

Compressor, conveyor, pulsating load |

Uneven load - 8 hours/day service, Moderate shock or |

1.5 |

2.0 |

2.5 |

|

C |

Presses, crushers, impact loads, |

Heavy shock load - 8 hours / day service, High peak |

2.0 |

2.5 |

3.0 |

Versatile Application Across Industries

Roller Chain Flexible Couplings are widely utilized in power transmission, machinery coupling, conveyors, and a broad spectrum of industrial equipment. Their adaptability allows for seamless performance in diverse environments where alignment and vibration control are essential. Whether deployed in factory automation or heavy equipment, these couplings provide reliable service under challenging conditions.

Durable Construction and Surface Options

Engineered from carbon or alloy steel, these couplings undergo specialized surface treatments such as black oxide, zinc plating, or phosphating. These finishes enhance resistance to wear and corrosion, ensuring a long operational lifespan even in demanding industrial settings. Precise machining guarantees optimal fit and efficient energy transfer.

Customizable Fit and High Performance

Available with pilot or finished bores and a range of diameters (inner: 1955 mm, outer: 75200 mm), these couplings are tailored to specific needs. Their robust structure supports speeds up to 3,500 RPM and torque from 70 Nm to 2,100 Nm, making them suitable for various mechanical loads and motion requirements in industrial applications.

FAQs of Roller Chain Flexible Coupling:

Q: How does a roller chain flexible coupling function in power transmission applications?

A: A roller chain flexible coupling transmits torque between two shafts while accommodating slight misalignments and absorbing vibrations. Its design, which includes a roller chain and sprocket ends, maintains strong mechanical connection, ensuring efficient power transfer and reduced risk of equipment damage caused by misalignment.Q: What are the main benefits of using a roller chain coupling in machinery and conveyor systems?

A: Key advantages include its ability to handle misalignments, absorb shock loads, and provide reliable operation at high speeds and varying torque requirements. Additionally, its modular, round structure and standard-compliant build make maintenance easy and improve equipment longevity.Q: When should you consider choosing a surface treatment like black oxide or zinc plating for your coupling?

A: Surface treatments such as black oxide and zinc plating offer enhanced resistance against rust and chemical exposure. These finishes are recommended when the coupling will be exposed to harsh environments, moisture, or corrosive agents, thus extending its service life and maintaining performance.Q: Where are roller chain flexible couplings most commonly installed?

A: These couplings are widely installed in power transmission systems, industrial conveyors, various machinery, and automated equipment where reliable and flexible shaft connections are essential. Their versatile design aligns with multiple international standards, making them suitable for a range of industries.Q: What is the typical process for selecting the right roller chain coupling size and bore?

A: Selection depends on parameters like required torque, shaft size, operational speed, and the applications alignment needs. Customers provide inner and outer diameter requirements according to their equipment (commonly 19 mm55 mm ID, 75 mm200 mm OD), and the manufacturer recommends a model with compatible specifications.Q: How do users benefit from the machined, round structure and absence of internal sealing?

A: The precisely machined, round structure ensures perfect fit and alignment, reducing wear and energy loss. The absence of internal sealing facilitates easy installation, inspection, and maintenance, making the coupling a practical choice for regular use and quick servicing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS