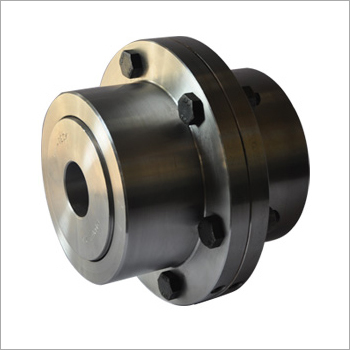

Full Flexible Gear Couplings

Product Details:

- Connection Shaft to Shaft

- Head Code Round

- Bore Customizable as per shaft size

- Thread No Thread

- Max. Speed Up to 8000 RPM RPM

- Sealing Protected with gasket/seals

- Material Alloy Steel / Carbon Steel

- Click to View more

Full Flexible Gear Couplings Price And Quantity

- 1 Unit

- 25000.0 INR/Unit

- Long with minimal maintenance

- Angular, parallel and axial

- Custom coupling for all shaft assemblies

- Grease packed or oil as specified

- Varies per coupling size (approx. 2 kg to 150 kg)

- -20C to +120C

- Varies by model, optimized for load distribution

- Anti-corrosive coated

- Spline/Precision bored

- Horizontal or vertical

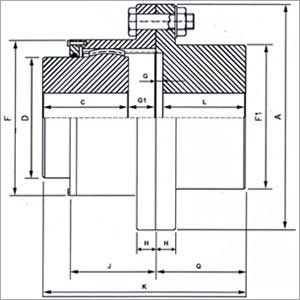

Full Flexible Gear Couplings Product Specifications

- Other

- Protected with gasket/seals

- Up to 8000 RPM RPM

- No Thread

- Machined

- Industrial power transmission, compressors, conveyors, pumps, fans, steel and cement plants

- Full flexible, double hub with sleeve

- Customizable as per shaft size

- Round

- DIN, AGMA

- Available from 20 mm onwards Millimeter (mm)

- Alloy Steel / Carbon Steel

- Cylindrical

- Shaft to Shaft

- Long with minimal maintenance

- Angular, parallel and axial

- Custom coupling for all shaft assemblies

- Grease packed or oil as specified

- Varies per coupling size (approx. 2 kg to 150 kg)

- -20C to +120C

- Varies by model, optimized for load distribution

- Anti-corrosive coated

- Spline/Precision bored

- Horizontal or vertical

Full Flexible Gear Couplings Trade Information

- Cash on Delivery (COD), Cash in Advance (CID), Cheque

- 100000 Unit Per Month

- Days

- All India

Product Description

Full Flexible Gear Couplings is a heavy duty mechanical device which is used to join two geared elements for the transmission of the rotational torque coming from the main driving source in between the two collinear shaft to give motion to the component parts within the machine. This machine component is fabricated by using heavy engineering materials which gives higher strength and durability. It is provided with flanged sleeve which makes it very easier to join the two halves rigidly with the help of mechanical fasteners.

Service Factor

Driven Unit (Machinery)

LIGHT :

- Uniform steady load never exceeding horse rating.

- Infrequent starting.

- Agitators, Blowers, Can Filling Machines, Conveyors, Fans, Generators, Pumps, Steering Gears, Stokers.

MODERATE :

- Heavy inertia, moderate shock, frequent starting.

- Peak loads do not exceed 125% average horsepower.

- Uneven load: Ctheadonveyors, Feeders, Welding, Laundry Washers, Mixers, Paper Mills, Printing Presses, Screens, Textile Industry, Car Pullers.

HEAVY :

- Heavy shock conditions or frequent reversing peak loads do not exceed 150% average horsepower.

- Uneven load.

- Cranes & Hoists, Crushers, Dredges, Elevators, Hammer Mills, Lumber Industry,

- Machine Tools, Metal Mills, Oil Industry, Rubber Industry, windlass.

Specification

|

Primer Mover |

||

|

Electric Motoror Steam Turbine |

Gasoline or Diesel Engine 4 or mor cyl. |

Gasolineor Diesel Engine more then 6 cyl. |

|

1.0 |

1.5 |

2.0 |

|

1.5 |

2.0 |

2.5 |

|

2.0 |

2.5 |

3.0 |

Engineered Precision for Industrial Demands

Our full flexible gear couplings are machined to stringent standards, such as DIN and AGMA, delivering precise load distribution even under extreme conditions. The spline or precision bored hubs, combined with double hub and sleeve structure, ensure seamless torque transmission amidst high misalignment, making them ideal for modern industrial setups.

Optimized Performance & Long-Term Reliability

These couplings feature grease-packed or oil lubrication options, sophisticated anti-corrosive coatings, and durable gasket or seal protection, extending their operational life in tough environments. Designed for horizontal and vertical mounting, each coupling supports high rotational speeds up to 8000 RPM and torque loads as high as 200,000 Nm, offering peace of mind and reduced maintenance costs.

Custom Compatibility for Every Shaft Assembly

No matter your shaft specifications, our couplings are custom-built to fit a wide range of inner and outer diameters, with cylindrical, round head designs. Theyre compatible across shaft-to-shaft connections and adaptable for high-demand industries such as steel, cement, compressor units, and power transmission systems worldwide.

FAQs of Full Flexible Gear Couplings:

Q: How does a full flexible gear coupling manage angular, parallel, and axial misalignment?

A: Full flexible gear couplings compensate for angular, parallel, and axial shaft misalignments through their double hub and sleeve structure. The gear teeth mesh effectively to allow movement and distribution of loads, ensuring reliable power transmission even when shafts are misaligned.Q: What surface treatments are applied to these couplings for corrosion resistance?

A: The couplings are available with multiple anti-corrosive finishes, including blackodised, phosphatised, and natural coatings. These treatments protect the alloy or carbon steel structure against harsh industrial environments, enhancing longevity and performance.Q: When should grease or oil lubrication be specified for these gear couplings?

A: Lubrication choice depends on the operating conditions. Grease-packed couplings are suitable for standard operating environments, while oil lubrication may be specified for high-temperature or heavy-duty applications to maximize service life and performance.Q: Where can these gear couplings be used in industrial applications?

A: These couplings are ideal for compressors, conveyors, pumps, fans, and heavy equipment in steel and cement plants or any industrial system requiring robust power transmission and misalignment tolerance.Q: What is the process for customizing the bore and size of a coupling?

A: Customization involves specifying your shafts dimensions, desired inner and outer diameters, and load requirements. Our engineering team then precision machines the coupling to match these needs, ensuring optimal compatibility and performance.Q: How do the gasket and seal protection systems benefit the gear couplings service life?

A: Gaskets and seals safeguard the couplings interior from contaminants such as dust, moisture, and chemicals. This protection minimizes wear and extends the couplings operational lifespan by maintaining optimal lubrication and preventing corrosion.Q: What are the key advantages of using a full flexible gear coupling in high-torque industrial environments?

A: Key benefits include high torque capacity up to 200,000 Nm, misalignment tolerance, customizable fit, anti-corrosive protection, low maintenance, and long service life, making them indispensable for demanding industrial power transmission applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS