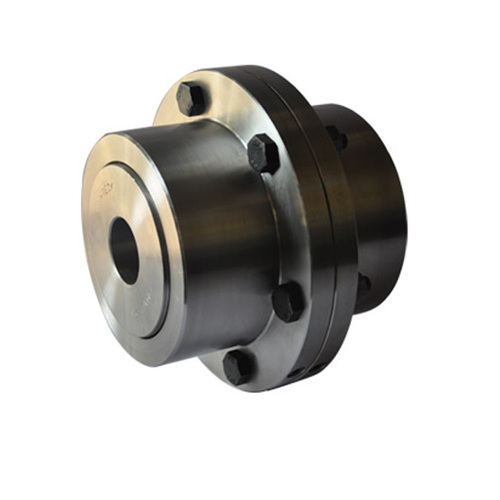

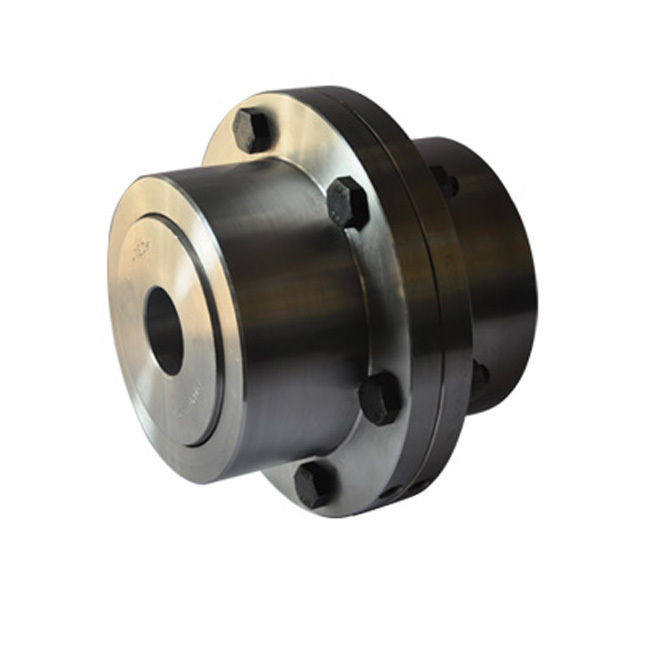

FULL Flexible Gear Couplings

25000.0 INR/Unit

Product Details:

- Torque Up to 430,000 Nm

- Bore Customizable as per requirement

- Sealing Oil Seal or Grease Seal

- Connection Flanged

- Head Code Round

- Max. Speed Up to 6000 rpm

- Material Steel

- Click to View more

X

FULL Flexible Gear Couplings Price And Quantity

- 25000.0 INR/Unit

- 1 Unit

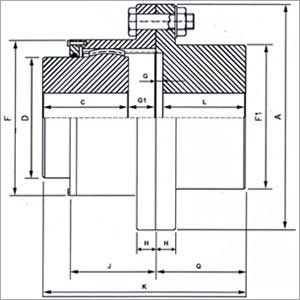

FULL Flexible Gear Couplings Product Specifications

- Black Oxide or Phosphated

- Machined

- Customizable as per requirement

- Up to 900 mm

- Up to 430,000 Nm

- Up to 6000 rpm

- Round

- Steel

- DIN 740, AGMA, or equivalent

- Industrial Power Transmission

- 4.5 TO 3100 Kilograms (kg)

- Up to 600 mm

- Gear

- Flanged

- Oil Seal or Grease Seal

- Round

- Gear Couplings

FULL Flexible Gear Couplings Trade Information

- 100000 Unit Per Month

- 1 Week

- All India

- ISO, MSME.

Product Description

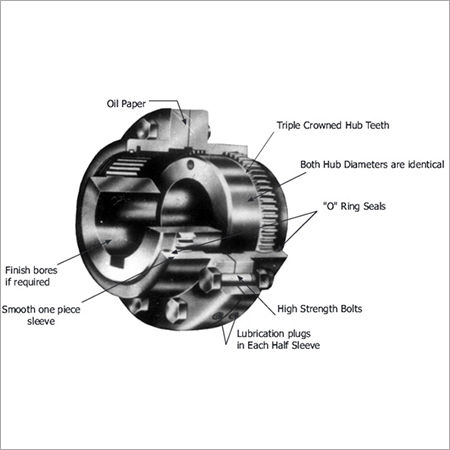

Crowned teeth gear couplings feature specially shaped gear teeth with a slight convex curve, known as a crown, on both the internal and external gears. This design optimizes contact between the teeth, reducing wear and enhancing torque transmission efficiency while accommodating misalignments. The crowned teeth help distribute loads more evenly, minimizing stress concentrations and improving the couplings overall durability. Crowned teeth gear couplings are commonly employed in applications where misalignment and high torque transmission are prevalent, providing reliable performance and extended service life.

Superior Transmission Performance

Specifically designed for industrial power transmission, these flexible gear couplings accommodate significant misalignments and high torque loads. Their robust steel structure and hardened teeth ensure endurance and minimal wear, delivering consistent, long-term performance across various applications.

Custom Solutions for Varied Applications

Our couplings are adaptable, with customizable bore sizes (up to 600 mm inner diameter, 900 mm outer diameter) and weights ranging from 4.5 kg to 3100 kg. This flexibility, along with multiple sealing and surface treatments, makes them suitable for a broad range of machines and environments.

FAQs of Flexible Gear Couplings:

Q: How do flexible gear couplings handle misalignment during industrial operations?

A: Flexible gear couplings are engineered to accommodate angular misalignments up to 1.5 and parallel misalignment up to 0.5 mm. The gear design allows for smooth torque transmission even when shaft alignment isnt perfect, preventing undue stress or damage to equipment.Q: What are the lubrication requirements for these couplings?

A: These couplings can be lubricated with either grease or oil, as specified for your operating conditions. Proper lubrication is essential for minimizing wear on the teeth and maintaining optimal service life. Regular maintenance and checking lubricant levels are advised for best performance.Q: When should a flexible gear coupling be selected over other coupling types?

A: Flexible gear couplings are ideal when you need to transmit high torque under misalignment conditions and require high durability. Their robust design, customizable options, and resistance to harsh environments make them preferable in heavy industrial applications where reliability is crucial.Q: Where are these gear couplings primarily used?

A: These couplings are used across various industries in India and globally for industrial power transmission. Common applications include heavy-duty machinery, pumps, conveyors, and drive systems that demand reliable torque transfer and accommodate misalignment.Q: What benefits do the anti-corrosive coating and hardened teeth provide?

A: The anti-corrosive coating protects the coupling from environmental degradation, while teeth hardened to 45-55 HRC ensure resistance to wear and mechanical stress. These features collectively enhance service life and reduce maintenance requirements.Q: What is the process for ordering a custom flexible gear coupling?

A: Clients can specify requirements for bore size, connection type, sealing, and finish. Once details are provided, our manufacturing team in India will design, machine, and finish the coupling to order, following relevant standards (DIN 740, AGMA, etc.).Q: How does proper maintenance extend the service life of these couplings?

A: Regular inspection, cleaning, and relubrication prevent premature wear of the gear teeth and seals. Ensuring alignment checks and replacing lubrication as needed can help these couplings operate reliably for an extended period, optimizing return on investment.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS